Black Commercial Weight Lifting Mat 4′ X 8′ X 1/2″ – Rubberlogix (RL-4812)

$76.00 Original price was: $76.00.$53.20Current price is: $53.20.

- Green products, guaranteed.

- Fast, friendly, always here to help.

- Excellent customer service online in a timely manner

- Online customer care, always here for you.

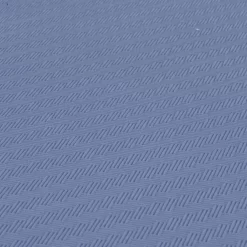

Rubberlogix 4′ x 8′ x 1/2″ Black Commercial Weight Lifting Mats – Rubberlogix USA Made Weightlifting Mats for commercial gyms are constructed from 100% recycled rubber. By reclaiming used tires and processing them into weight lifting mats, each year we save thousands of tires from being buried in our nation’s landfills.

I see that shipping cost is based on my destination, so what will be my “delivered” price per mat?

Weighing just under 96 pounds each, single deadlift mats require additional handling with UPS for ground shipments due to size and weight. Mats ship from warehouse in North Carolina, so total pricing to Eastern states will be less than that to Central, Southern, or Western states. If you are only ordering a single mat, you can estimate your total DELIVERED price (price of mat AND shipping cost together) to be the following based on major metropolitan regions:

- $259.00 – West Coast

- $209.00 – East Coast

*Shipping cost per mat is greatly reduced as the quantity of mats is increased.

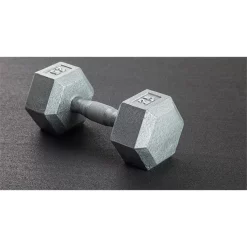

Why purchase weight lifting mats for your gym? – Protecting floors from weight drop, whether in a home or commercial gym, is essential in keeping floors from being damaged and prolonging the life of weight lifting equipment such as kettlebells, dumbbells and barbell sets. A 4′ x 8′ x 1/2″ mat offers a large 32 sq. ft. area of protection. Use them on either side of a dumbbell bench, under bench presses and squat racks. The 1/2″ thick solid rubber handles impact from larger size weights and also acts as a great shock absorber underneath plate loaded equipment for additional stabilization and sound deadening.

Using multiple 4′ x 8′ x 1/2″ rubber mats to cover an entire floor:

For complete floor protection under your free weight and cardio equipment areas, heavy duty recycled rubber gym equipment mats will do the job and then some. And since the mats are so big and heavy there is no need to use adhesive. Normally during the manufacturing process block mats are cut by hand, and are not always going to be exact dimensions in length and width, or have edges that are totally squared. In the case of a single mat or only a few mats, this is not generally noticeable. However, when multiple mats are laid side-by-side and end-to-end across a gym floor, the end user may experience gaps here and there resulting from less precisely cut edges being positioned next to each other. These gaps can trap dust and dirt, and in general create a less than ideal visual appearance. In many livestock and other industrial applications where function outweighs aesthetics (such as horse stalls and machine shops) this does not matter. However, in a fitness setting (such as a crossfit box, commercial fitness center, or military base gym) where 4′ x 6′ or even 4′ x 8′ block mats are utilized as “jumbo” loose-lay tiles to cover a large surface area of flooring, a more finished look is often desired. In this bulk purchase scenario it is recommended to have the mats “trued” to consistent size during manufacturing. The process of “truing” via waterjet cutting puts the mats through a very precise method of production for straight, sharp edges and square corners, allowing much more consistency from mat to mat greatly reducing visible gaps and any other seam inconsistencies when installed. When requesting your flooring quote, let your IRON COMPANY® flooring sales rep know if your mats need to be trued.

Truing Lead Time: Please allow additional 4 weeks truing lead time prior to shipping since mats need to be custom produced to order and put through waterjet cutting process

Be the first to review “Black Commercial Weight Lifting Mat 4′ X 8′ X 1/2″ – Rubberlogix (RL-4812)” Cancel reply

Related products

Adhesives / cleaners / tools

Aerobic flooring tiles

Modular Interlocking Plastic PVC Tile Beveled Corners | IRON COMPANY (BEV-CORNER)

Foam exercise mats

Smooth Surface Floor Exercise Mat With Straps — Aeromat (71401-71403)

Adhesives / cleaners / tools

Sure-Grip Double Sided Rubber Flooring Adhesive Tape Roll – Seaming Tape – Ultimate RB Rubber (TAPE)

Foam exercise mats

-

- Strength Equipment

- Selectorized equipment

- Plate loaded / leverage equipment

- Weight benches

- Combination gym equipment

- Abdominal core benches

- Functional training

- Power cages / platform racks

- Half racks / quarter cages

- Back / ham / glute benches

- Jungle gyms

- Smith machines

- Squat stands / modular racks

- Home gyms

- Weightlifting platforms

- Weight bench attachments

- More Products

- Accessories

- Storage Racks

- Balls / Slammer / Medicine

- Cross Training / Boxing / MMA

- Weight Scales

- Bodyweight / Calisthenics

- Bands / Tubing / Rings

- Cleaning Wipes / Supplies

- Plyometric / Speed / Sled

- Foam Rollers / Balance

- Inversion / Vibration

- Wireless Entertainment

- Heavy Ropes

- Yoga / Pilates

- Latest Products

- Free Weights

- Cardio Equipment

- Gym Flooring

- Login

Reviews

There are no reviews yet.